A two-armed robot named Tarzan, swinging along elevated cables, could allow farmers to monitor fields continuously at lower cost while avoiding interference with plants.

By John Tibbetts | Photos by Ai-Ping Hu and Jason Maderer

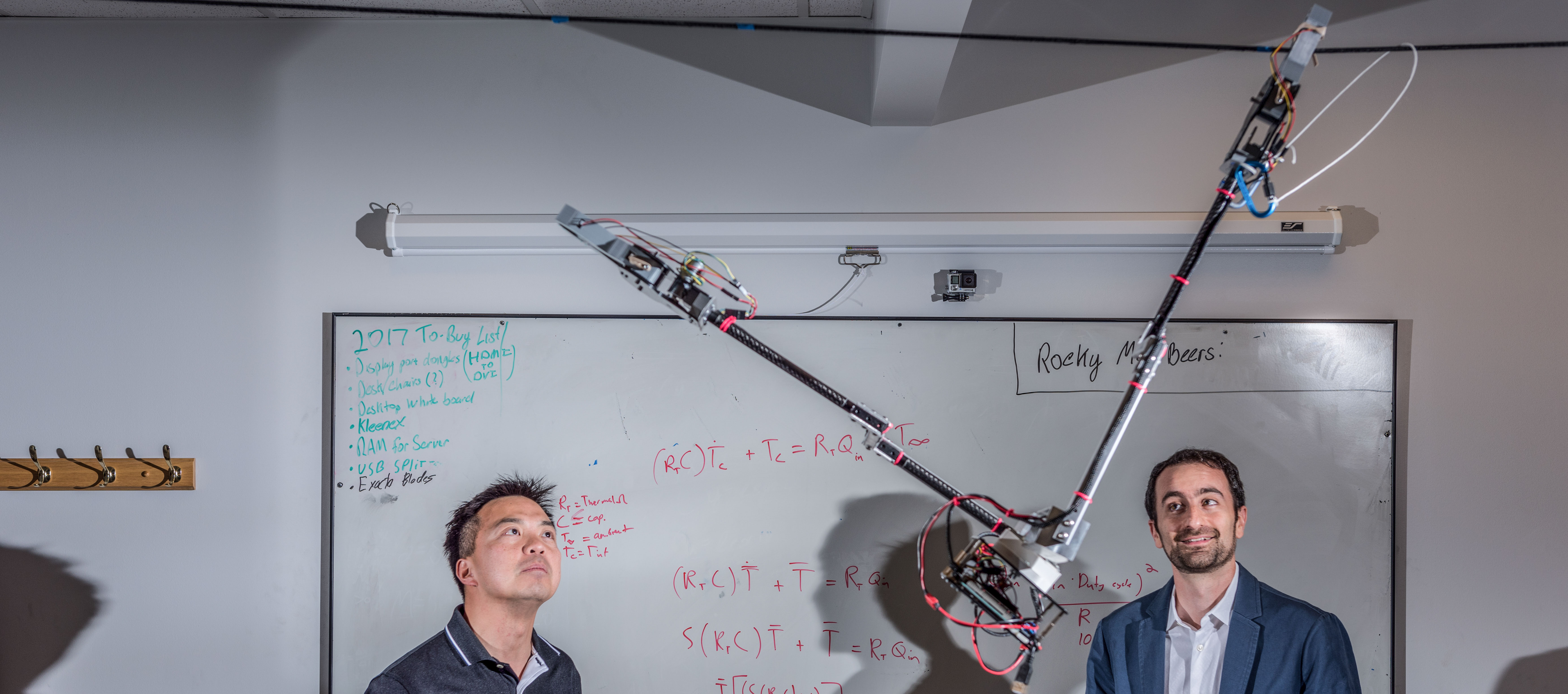

“Swinging – or brachiation – is an energy-efficient way to travel because gravity is doing most of the work,” said Ai-Ping Hu, a senior research engineer at the Georgia Tech Research Institute (GTRI). The lightweight robot has aluminum arms and 3D-printed hands with sensors. The eight-pound robot swings back and forth with one hand on the cable, gaining momentum until its second hand detects the cable overhead and grips it. This swinging motion replicates a gibbon’s movement along a tree limb or vine.

During the second half of each swing, gravity’s downward pull slows Tarzan’s arc until the gripper engages the cable. Tarzan’s camera, housed in the payload at the joint intersection of the arms, photographs crops below, sending images to a computer for analysis. The robot swings again, gathering momentum until its other hand can grab the cable an arm’s length away. In this way, Tarzan makes its way through the entire field.

“This is a unique, emerging technology for agriculture that could provide a paradigm change in how we think about robots,” said Jonathan Rogers, an assistant professor in the Woodruff School of Mechanical Engineering at Georgia Tech. “It could help us move away from the single, heavy, expensive robot systems of autonomous tractors with big tires needed to navigate in difficult terrain – instead we could use small, energy-conserving robots that collaborate among themselves and with people. Small robots like this do not require a lot of energy, allowing them to be in the field 24/7 without people telling them what to do.”

Tarzan’s camera is able to shoot high-resolution images of individual plants that can be analyzed with machine-learning algorithms to detect diseases or other stresses before these hazards spread throughout the field.

During the 2017 growing season, for instance, Tarzan was swinging above a soybean research field at the University of Georgia. Tarzan’s camera photographed individual plant leaves to help scientists grow more drought-tolerant crops from among the genetic lines provided by a seed company.

University of Georgia plant geneticists looking for phenotype indicators of drought tolerance found information in two ways: in thermal images identifying the temperature of individual leaves and in color images showing leaf wilt or droopiness. Plants are droopier when they receive too little water or aren’t making adequate use of the limited water that they have. From these image data, the seed company chooses the most drought-tolerant plants and propagates those genetic lines.

Someday the robot might function as a mobile scarecrow to recognize, track, and drive off pests or predators. In another potential development, a farmer could receive daily information on a computer or smartphone from a geo-referenced robot swinging over fields in a completely automated system.

In the future, Tarzan’s swing will become even more efficient. In the field, Tarzan travels best on a relatively taut wire held down with hefty anchors, but that may not be practical in field conditions where soils are loose.

“If we make the anchors bigger and heavier and the wire with higher tension, that will be costly for the farmer, especially if there are a lot of large number of cables in a field,” said Hu. “But a looser cable presents challenges in software control because Tarzan faces difficulty in moving along a wire that’s oscillating six inches up and down.”

The researchers plan to adjust Tarzan’s software controls to take better advantage of the wire’s oscillation, which could enhance swing efficiency and save more energy. Some early simulation results indicate that there is a potential to have the oscillating cable inject energy into the robot system.

The researchers also plan to add wrists to Tarzan, so the robot can turn 90 degrees and swing onto an adjacent cable. “That’s never been done before,” said Hu. “It would allow a robot to break out of the 1D linear world and enter into a 2D planar world.” Instead of a robot swinging along a single wire, the robot could move also between wires over every row in the field. “The robot could swing from one wire to the next, eventually monitoring an entire field over the course of a day as it looks for disease and pests.”

This work has been sponsored by a seed grant from Georgia Tech’s Institute of Robotics and Intelligent Machines (IRIM).